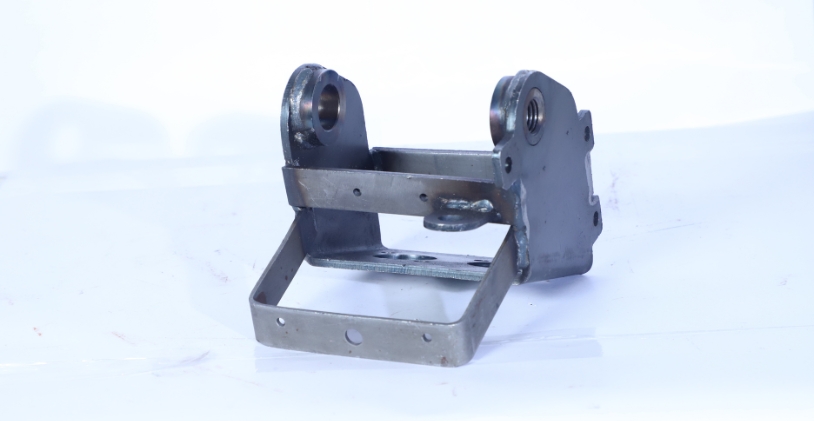

Custom Tools & Pressed Parts

Engineered for accuracy, built for resilience — our custom tools and pressed metal parts are the backbone of advanced automotive manufacturing. Designed to meet the exacting demands of today's OEMs and Tier-1 suppliers, these components are precision-cut, formed, and finished for seamless integration.

Whether it’s small-batch tooling or high-volume pressed parts, our team delivers tailored solutions that ensure reliability, repeatability, and optimal fit in your assembly line or product ecosystem.

Engineered to Fit Flawlessly

Every part is manufactured with high dimensional accuracy to ensure seamless compatibility with diverse automotive assemblies.

Built for Long-Term Use

High-strength materials and tested processes ensure durability even in high-stress, high-volume production environments.

Manufacturing Meets Tailored Innovation

From tool design to production runs, every stage is optimized to deliver precision and consistency—helping your products meet global performance standards.

- Precision Pressing: High-tolerance forming for accurate part shapes

- Custom Tooling Solutions: Die and tool fabrication suited to unique project requirements

- Material Versatility: Compatible with a wide range of automotive-grade metals

- Batch Flexibility: From prototypes to production-scale output

Ideal For

Requiring exact-fit pressed components for large-scale manufacturing.

Needing tailored solutions for specialty part production.

Looking for consistent, high-quality metal components at scale.

Working on precision prototypes and custom tool applications.

Where strength, accuracy, and endurance are non-negotiable.